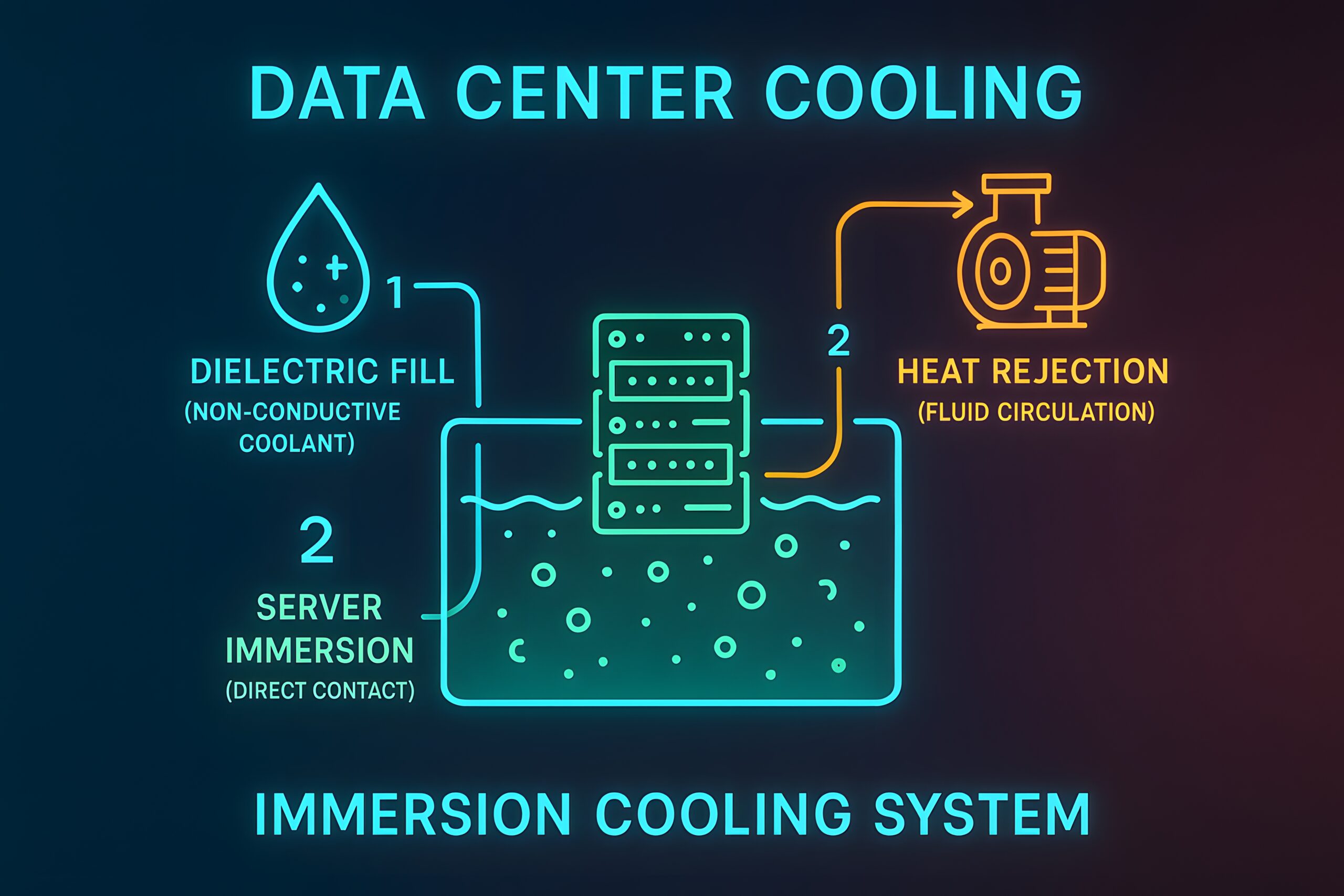

As data centers pivot toward direct-to-chip (DTC) and immersion cooling to handle the heat of next-gen GPUs, the data center “plumbing” is being pushed to its physical limits. Data center operators are moving away from simple chilled-water systems toward specialized dielectric-fluid and treated-water loops.

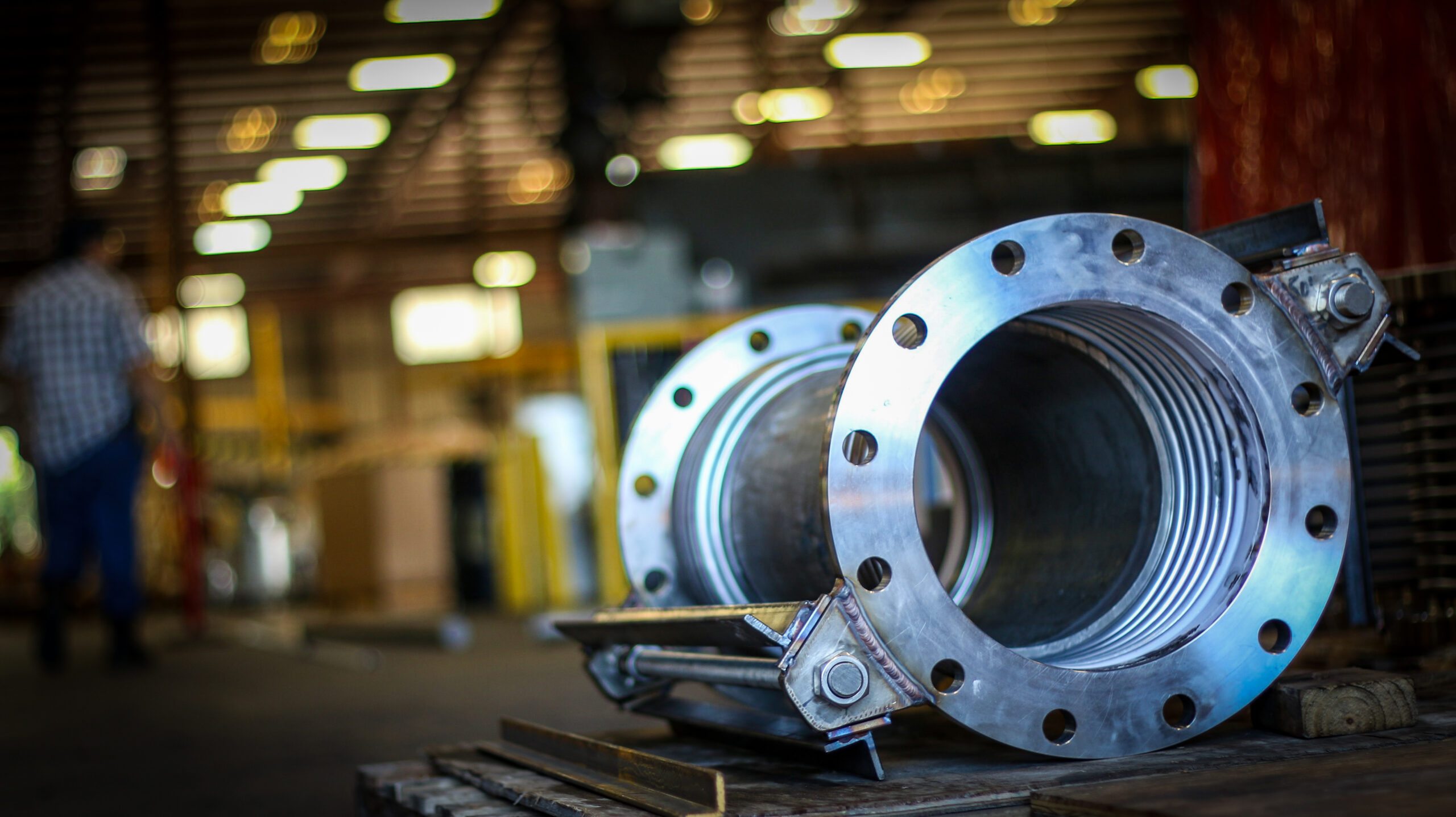

In this environment, the choice of expansion joint material is both an important procurement detail and a strategy for long-term viability. While rubber expansion joints may survive a standard office HVAC system, critical high-performance computing (HPC) loops require the chemical resistance of 300-series stainless steel or Inconel.

Navigating the Chemistry of Modern Cooling Fluids

The shift to liquid cooling introduces a complex variable: chemical compatibility. Whether you use propylene glycol blends or specialized immersion oils, the elastomers in traditional gaskets and rubber joints can degrade, leach, or become brittle over time.

The Case for 300-Series Stainless and Inconel

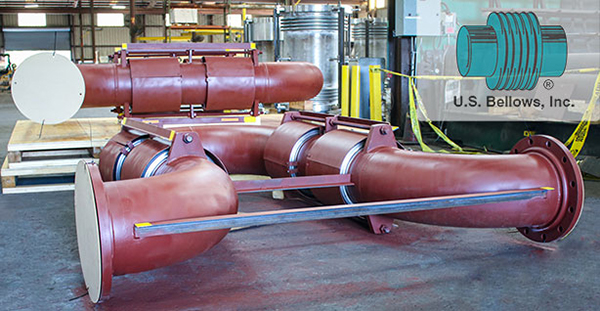

Metallic bellows, specifically those engineered from Type 304 or 316L stainless steel, provide an inert surface that won’t react with modern coolants. In ultra-aggressive environments or systems where chloride-induced stress-corrosion cracking is a risk, Inconel 625 provides even greater protection. These materials ensure that no particulates enter the loop stream due to corrosion or degradation—a necessity when the cooling channels on a cold plate are measured in microns.

Engineering for the Infinite Loop: Fatigue and Cycle Life

In an HPC environment, thermal loads are non-stationary. As workloads spike during AI training runs and drop during idle periods, the piping system undergoes constant thermal expansion and contraction. This is where cycle life becomes the most important metric you’ve never heard of.

Mastering the Thermal Pulse

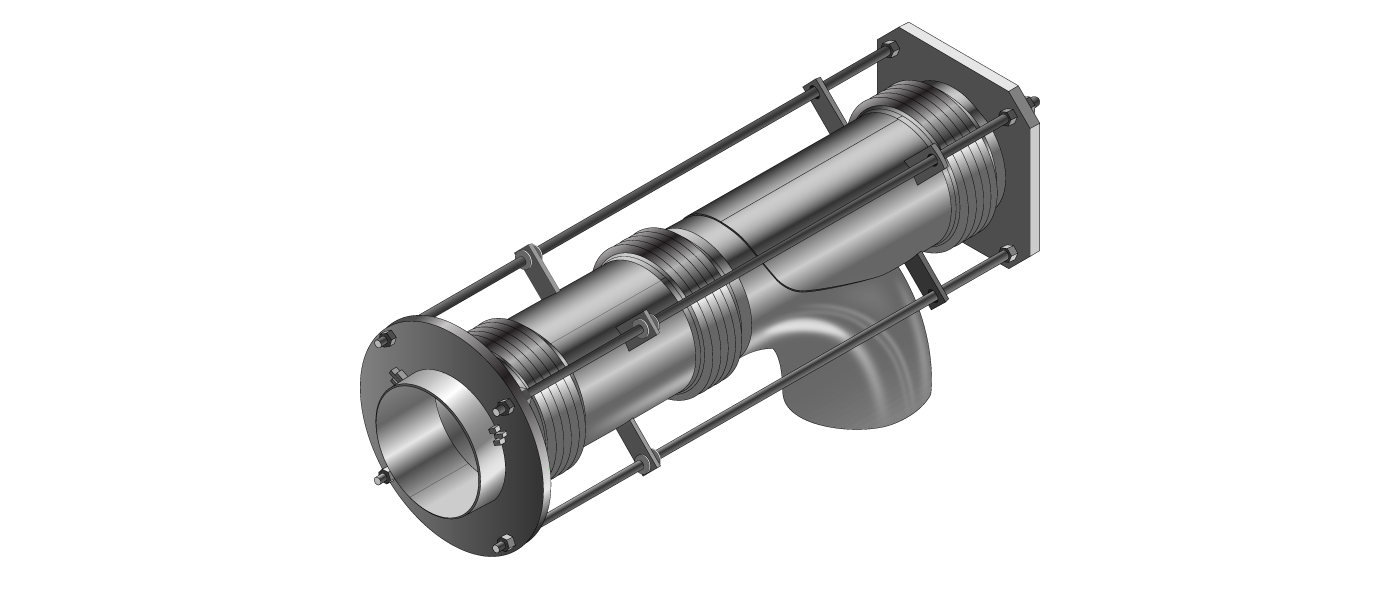

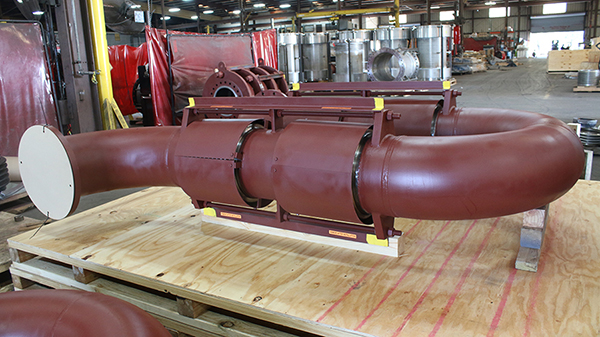

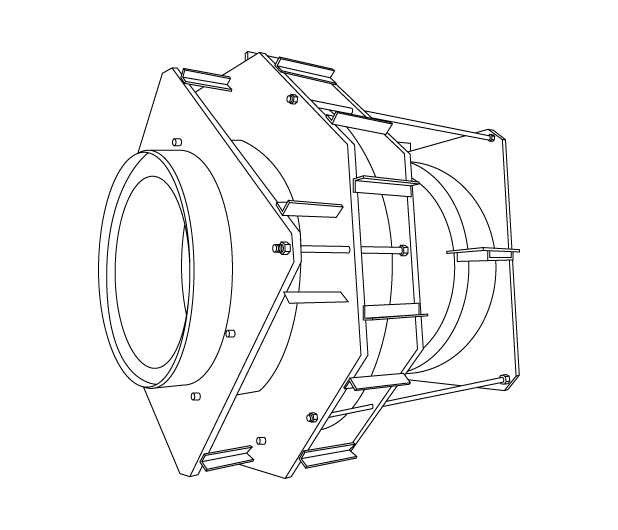

Unlike rigid piping, a metallic expansion joint is engineered as a flexible pressure vessel. Each convolution in the bellows is designed to evenly distribute stress, while containing the pressure of the line. By using the design temperature to estimate the line’s movements and the frequency of power cycles, our engineers can design a bellows with a rated cycle life in the tens of thousands. This prevents fatigue cracking: the microscopic failure of the metal grain structure, and ensures that the joint lasts as long as the data center itself, not just the current server generation.

FAQ: Critical Insights for Liquid Cooling Infrastructure

How does dielectric fluid creep affect expansion joint seal selection?

A: Dielectric fluids have lower surface tension than water, making them prone to creep through standard gaskets. Effective designs use convoluted metallic bellows with welded ends rather than flanged mechanical joints to ensure a zero-leakage environment.

Can metallic expansion joints be used in two-phase immersion cooling?

A: Yes. Because metallic bellows are hermetically sealed and are resistant to the high pressures and vapor phases of dielectric fluids (especially 316L), they are the preferred choice for sealing the integrity of two-phase cooling loops.

What is the typical lifespan of an Inconel-625 bellows in an HPC loop?

A: When properly engineered for the system’s thermal movements, an Inconel-625 bellows is often rated for a design life of 20+ years, far outlasting the 3–5 year refresh cycle of the IT equipment it cools.

Make sure your cooling infrastructure is ready for the next generation of power density.

Transitioning to direct-to-chip or immersion cooling is a complex leap, but your piping doesn’t have to be a source of stress. We help engineers bridge the gap between traditional HVAC and modern HPC reliability.

Let’s discuss your project’s unique requirements and find the exact bellows solution to keep your uptime at 100%. Contact our engineering team for a comprehensive review of your piping stress analysis and material compatibility requirements.

Read More

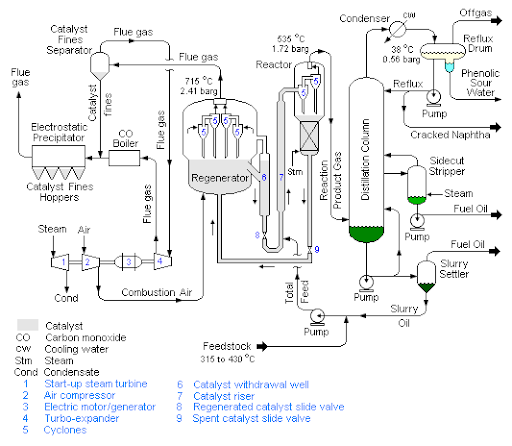

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

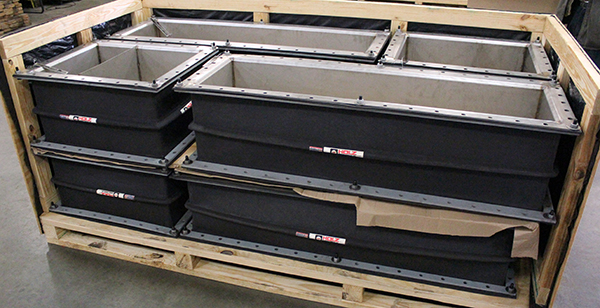

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for:

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for:

Refractory materials, typically ceramic or concrete, are designed to insulate and protect steel components from extreme heat. Yet, they possess a relatively low tensile strength and are highly susceptible to cracking and spalling when subjected to differential thermal movement.

Refractory materials, typically ceramic or concrete, are designed to insulate and protect steel components from extreme heat. Yet, they possess a relatively low tensile strength and are highly susceptible to cracking and spalling when subjected to differential thermal movement.