Fatigue Testing

|

|

This is a preliminary summary report describing fatigue testing conducted by U.S. Bellows, Inc. The objective of the fatigue test was to detect fatigue crack growth generated by compressions during controlled cycling on a fatigue-testing machine. |

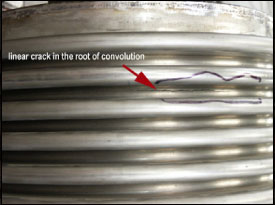

U.S. Bellows, Inc. conducted a fatigue test on 12” diameter A240 TP 321SS bellows with 8 convolutions. The EJMA calculations for this test was based on compressing the bellows 2.3/4” 1000 times. This bellows was attached to each side of the cylinder of the fatigue test machine and pressurized to 25 PSIG for the purpose of leak detection. This bellows failed in the root of the convolutions at 1,285 cycles.

|

|

| Figure 1 shows an overall view of the axial cycle fatigue test machine with bellows installed | Figure 2 shows a linear crack in the root of the convolution–about 3 inches long, which is typical of bellows low cycle fatigue) |

| This test has proven that U.S. Bellows Inc., EJMA cycle life calculation of 1,000 cycles is met. The actual cycle life of 1,285 cycles is higher than the EJMA Calculated cycle life. | |