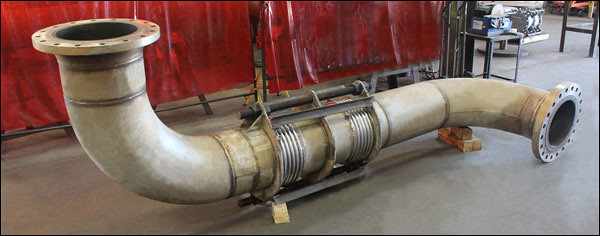

U.S. Bellows custom designed single expansion joints for an oil refinery in China. They were fabricated with Incoloy 800H bellows and ASTMA 240TP 304H stainless steel weld ends. The expansion joints have a diameter of 6″ with an overall length of 11″. The assemblies were designed for a spring rate of 362 lb./in., 1″ axial movement at 1112°F and 5 psig. All expansion joints were dye penetrant examined and hydro-tested prior to shipment.