|

HOW TO SELECT AND ORDER The first step in selecting the proper pipe expansion joint assembly is to collect and organize as much information regarding the design and operating parameters of the system as possible. As a minimum the following information should be provided: |

|||||

|

|

||||

|

EXAMPLE

|

|||||

|

|||||

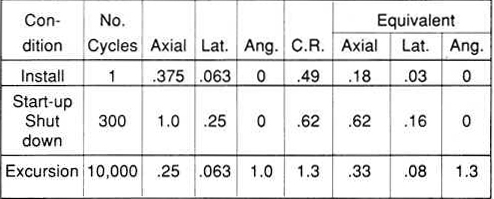

Total = 1.13 0.27 1.3

EQUIV. AXIAL EQUIV. LATERAL EQUIV. ANGULAR RATED AXIAL RATED LATERAL RATED ANGULAR

1.13 0.27 1.30 2.75 0.69 10.0

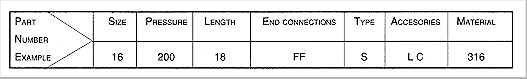

Part Number Example |

|||||

| |||||