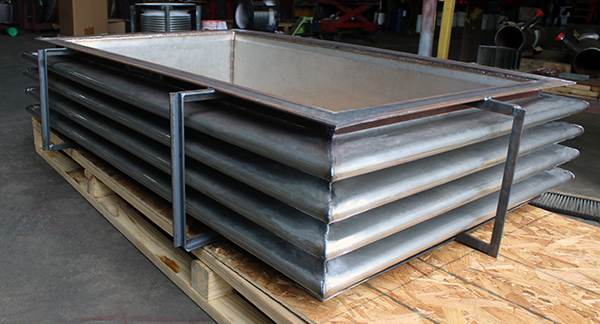

Type: Rectangular Expansion Joints Size: 37-3/8″ Wide | 65″ Long | 16″ FTF Material: 304 Stainless Steel | Carbon Steel Design: 250°F Operating Temperature @ 5 psig Testing: 100% Dye-Penetrant U.S. Bellows custom-designed two of these rectangular expansion joints for an air fan ducting application at a chemical facility in Texas. They are 37-3/8″ wide, 65″ long, and 16″ face-to-face. The bellows and liner were fabricated from 304 stainless steel, with the rest of the components from carbon steel. The units are designed for an operating temperature of 250°F at 5 psig. The expansion joints were 100% dye-penetrant tested prior to shipment.

Rectangular expansion joints have many applications in which they are used. They can be used in blast furnaces in steel processing facilities, APH Air preheaters in refineries, and for ducting in large systems in many industries in petrochem, mining, LNG and steel mills. We have built over 400 such units over the last couple of years of varying metallurgy ranging from carbon steel to stainless to inconel. We currently have inconel units in production for a large LNG facility to meet the newly established FERC requirements around spillage, environmental considerations, and, most importantly, safety.

Manufacturing expansion joints involves a precise blend of scientific principles and manufacturing craftsmanship. Rectangular expansion joints present distinctive challenges, particularly in relation to edge welding requirements. Without the necessary expertise, there is a risk of encountering issues such as sugaring—a form of oxidation that arises when an inadequate amount of purging gas is utilized during welding.

It’s worth noting that circumferential welds in typical round expansion joints, which are both welded and formed simultaneously, do not face the same concerns. In contrast, rectangular expansion joints undergo a two-step process where they are first formed and then welded, introducing unique considerations.

We conduct thorough in-house testing for all our expansion joints, encompassing a comprehensive range of assessments:

- Burst Testing

- Dye Penetration testing

- Fatigue/Cycle Testing

- Hydrostatic testing

- Helium Leak testing

- Ultrasonic Testing

- Radiography Testing

- PMI Testing

- Pneumatic Testing

- Magnetic Particle Testing

- Leak Detection Testing.

Rectangular expansion joints represent a subset of the assessments conducted for typical round expansion joints. Specifically, for rectangular expansion joints, we perform leak, hydro, and pneumatic testing.

PT&P REF. ORIGINAL POST 07222019