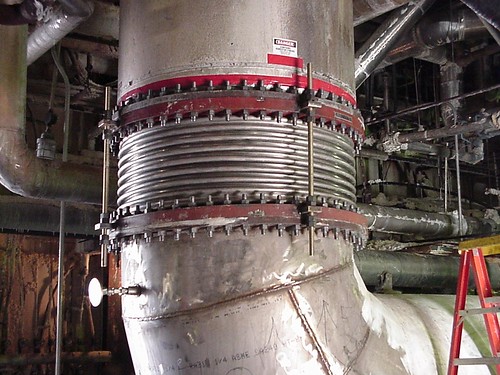

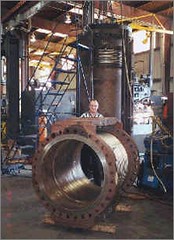

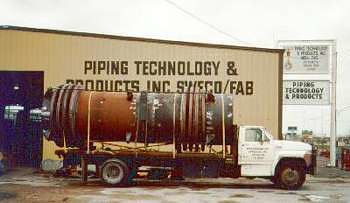

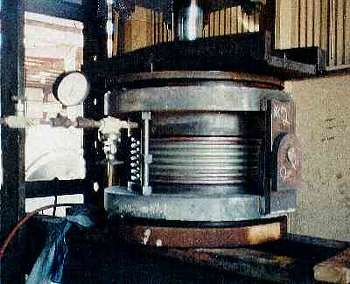

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc. rushed to an emergency call of an Alaskan petroleum firm. The firm called upon U.S. Bellows’ 24 x 7 Quick-Turn/Emergency service to aid them in the immediate replacement of a defective, 48″ diameter expansion joint when their G417 Pump failed suddenly during the plant startup.

The timeline of events demonstrates the quick engineering and manufacturing response from U.S Bellows:

07/21/00 (Friday) 5:30 p.m., U.S. Bellows receives an emergency call.

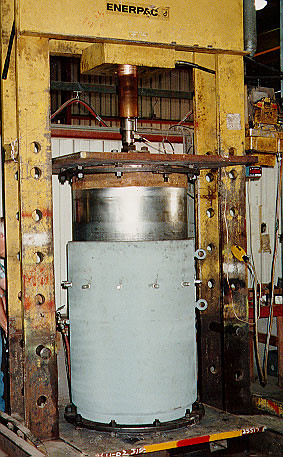

07/22/00 (Saturday) U.S. Bellows/ PT&P builds the 48″ diameter expansion joint and ships it to a location on the same day.

07/23/00 (Sunday) The 48″ diameter expansion joint designed and built by U.S. Bellows/PT&P was installed at a customer’s location.

The customer expressed great appreciation for the extraordinary efforts put forth by the individuals at U.S. Bellows. The on-call engineering and manufacturing team demonstrated its ability and commitment to servicing customers on an emergency basis.

U.S. Bellows is available on a 24 x 7 basis to fulfill any emergency requirements that might arise in the course of plant shut-downs or start-ups. The company has a system of stock bellows which can be used to assemble and ship different types of expansion joints including universal, elbow pressure balanced, and in-line pressure balanced expansion joints. The U.S. Bellows’ “on-call” engineering and manufacturing team is specifically equipped to handle rush and emergency orders. Using the unique web and Internet-based technology, the company is able to respond to any emergency requirements within 30 minutes of notification.

Read More