Rectangular Metallic Expansion Joints Extended Description

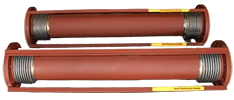

Rectangular metal pipe expansion joints have a variety of applications in the power, petrochemical, refining, chemical, and steel industries. Since there are no standard duct sizes, and due to the wide range of pressure and temperature combinations, each rectangular metal pipe expansion joint is custom-engineered to provide the most economical design that will absorb the thermal movements of the system in which it is installed. Like circular pipe expansion joints, rectangular pipe expansion joints absorb three types of movement: axial, lateral and angular. For the purpose of designing rectangular bellows, it is critical to know in which direction the lateral and angular movements will occur, i.e. parallel to the long and/or short side of the bellows.

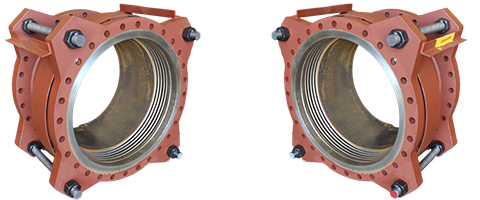

Unlike circular bellows where the pressure stress is a circumferential membrane (hoop) stress, the rectangular bellows must be designed for longitudinal (beam) bending stresses. Long unsupported lengths must frequently be supported to prevent excessive deflection and stresses of the bellows element. In certain applications, covers and liners can perform the function of pressure supports. Typical convolution geometry's and corner construction details are shown below. The "V" convolution profile will be supplied with single miter corners unless otherwise specified. Round corner bellows will always be constructed using the "U" convolution profile.