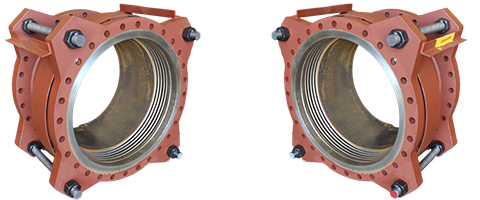

Refractory Lined Expansion Joints Extended Description

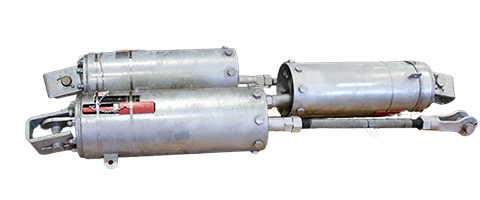

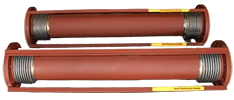

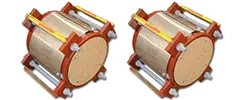

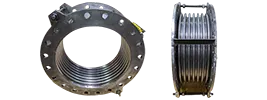

Depending on the temperature, pressure, movement and flow media conditions, refractory-lined pipe expansion joints can be hinged, in-line pressure-balanced, gimbal, tied-universal and can also include pantographic linkage. For hot applications (up to 1400°F), the bellows are packed with KO wool and lined with insulating refractory. The refractory-lining allows for the use of carbon steel pipe instead of 300 series stainless steel. It can reduce the pipe wall temperature to between 300-450°F and also protect the bellows from abrasion caused by the flow of abrasive particles. Refractory-lined expansion joints are used in Fluid Catalytic Cracking Units (FCCU), furnaces, hot gas turbines, styrene plants, fluidized bed boilers, kilns, power recovery trains, and thermal oxidizers. Refractory-lined expansion joints are custom designed for each application due to the extreme environments.