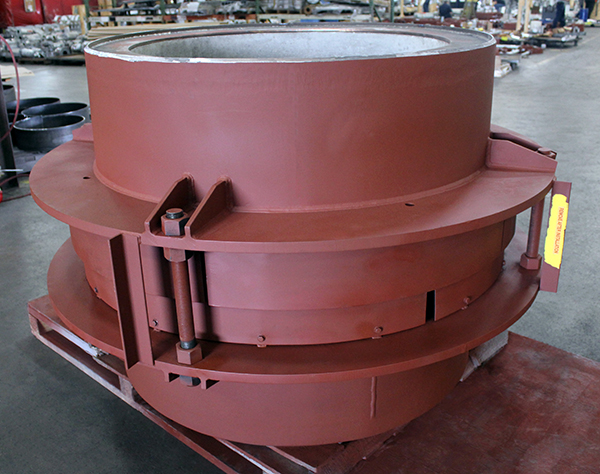

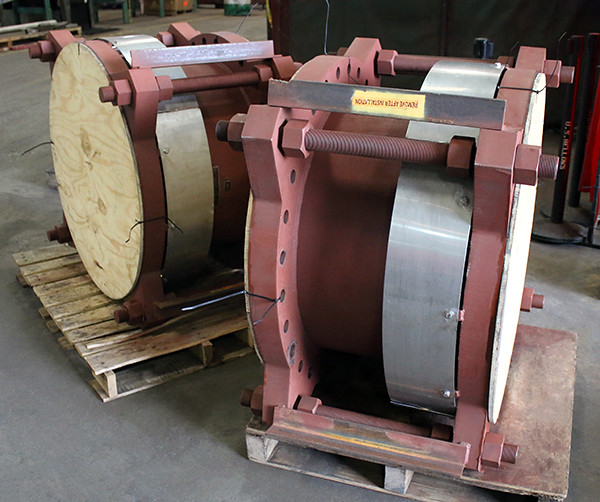

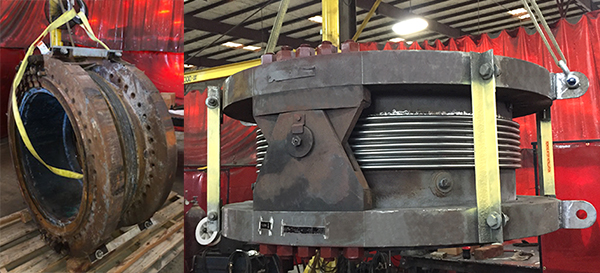

| Type: | Refractory-Lined Expansion Joint |

| Size: | 43″ Tall x 39-1/2″ Dia. |

| Material: | Carbon Steel | INCOLOY® 825 | 3.75″ Thick Refractory |

| Design | Operating Temp: 653°F at 46 PSIG | 0.25″ Axial Compression |

| Testing: | Hydro-tested | Q.C. Inspection |

This refractory-lined expansion joint was custom designed for a regenerator application in Uruguay. The unit is 43″ tall, 39-1/2″ in diameter, fabricated from carbon steel and the bellows are INCOLOY® 825. It is lined with 3.75″ thick insulating and abrasion-resistant refractory. It is designed for an operating temperature of 653°F at 46 PSIG and 0.25” axial compression. The expansion joint was hydro-tested at 68 psig prior to shipment.

Read More