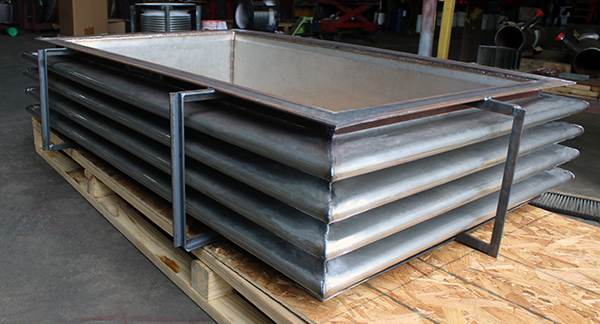

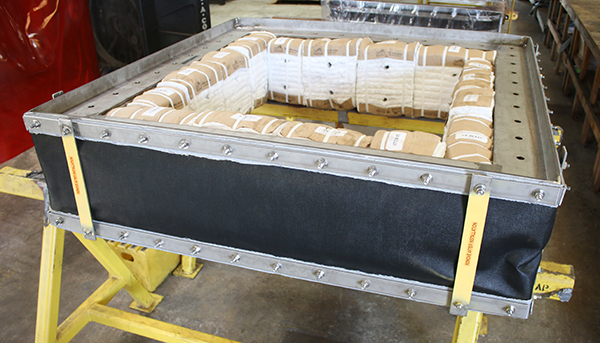

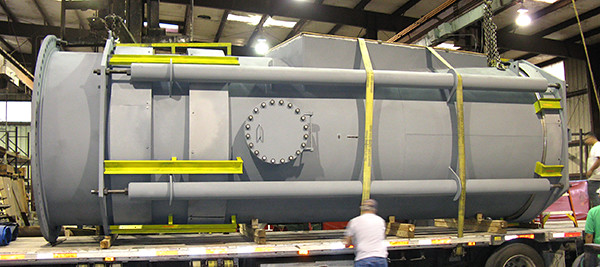

| Type: | Externally Pressurized Expansion Joint |

| Size: | 133 11/16″ and 120.5″ Long | Both Have 42″ Pipe Dia. |

| Design: | Inconel 625 | Carbon Steel |

| Material: | 450°F at 108 psig & 31″ and 25″ Axial Compression |

| Testing: | Hydro-tested at 167, PMI, 100% X-Ray, and Dye-Penetrant |

U.S. Bellows custom designed these externally pressurized expansion joints for a flare header application at a refinery in Mississippi. One unit measures 133-11/16" long and the other measures 120-1/2" long and both are manufactured for a 42" pipe diameter. The bellows were fabricated from Inconel 625 and used in conjunction with a carbon steel pipe per A671-CC-60 CL.22. The carbon steel pipe is finished with a 2-coat paint system for corrosion protection. They are manufactured for a design pressure of 108 psig at 450°F with 31" and 25" of axial compression. All alloy material was PMI inspected. The units were hydro tested at 167 psig, 100% dye-penetrant tested, and the bellows and pipe weld seams were 100% X-ray tested prior to shipment.

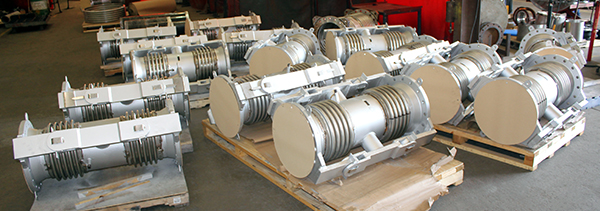

Expansion joint applications are varied depending on the type of plant. Some applications include:

- Exhaust systems for Aerospace, Trucks, Marine Piping

- Solid waste incineration for Renewables and Biofuel plants

- Waste Water Treatment plants for Municipal water districts as well as manufacturing plants

- Kilns in Mining, Food, and Plastics plants

- Geothermal Plants

- Gas Turbines

- FCC units

- Heat exchangers

- Steam distribution in Geothermal plants

- Water cooling systems for Nuclear power plants such as inlet of condenser cooling water from lakes or large bodies of water

- Thermal Oxidizer systems in polymer processing

- Boller Duct Expansions

- Vacuum Jacketed piping systems in LNG

We have built, supplied, installed, replaced, audited, repaired, and tested expansion joints for most piping systems applications. Our in-house expertise in handling different types of materials needed for expansion joints made of carbon steel, stainless, alloy steel, high nickel alloys, and aluminum spans over our 48 years of work. Welding specialties include TIG, pulse-arc MIG, SMAW, SUB-ARC, and Aluminium. Our qualifications for expansion joints are ASME Section IX, AWS D1.1, NS, and MIL-STD-248. Testing can specified to include any or all of the following depending on project and application requirements:

- magnetic particle-dry method

- Liquid penetrant-visible and fluorescent

- Ultrasonic and radiography

- Hydrostatic and Pneumatic testing

US Bellows, a subsidiary of Piping Technology and Products, is a member of the EJMA association which maintains a set of standards for quality expansion joint design and manufacturing. The standards are used as a worldwide reference for the proper selection and application of expansion joints.

PT&P REF. ORIGINAL POST 02202018

Read More